In today’s healthcare world, keeping patients safe and meeting strict rules is the top priority. Because of this, every little piece inside a medical device must work exactly as planned. That is why precision metal stamping parts-small, often unseen metal bits-matter so much. They provide the strength, fit, and smooth assembly that doctors and patients expect.

To produce these high-precision parts day after day, equipment makers count on reliable precision CNC machining suppliers. Their job is not just to cut metal; they must meet tight tolerances, control quality at each step, and deliver on time. In the sections that follow, we will look at why those tolerances are so critical in the medical field and how choosing the right machining partner can give a device maker a real competitive edge.

How Precision Metal Stamping Powers Medical Device Production

Metal stamping is a fast, cost-friendly method that shapes sheet metal into exact parts by pressing it between specially made dies. Inside the medical field, you will find these stamped pieces in:

- Surgical instruments

- Implantable devices

- Catheter components

- Monitoring equipment

- Battery enclosures

- Diagnostic tools

Unlike everyday gadgets, medical devices must meet rigid FDA rules and global standards. A single mistake even a tiny micron off can cause equipment to fail or, worse, put a patient in danger. For that reason, precision metal stamping parts are designed and made with tight tolerances so every piece fits the same, time after time.

Why Tight Tolerances Matter in Medical Assembly

In the world of medical-device assembly, tight tolerances mean every part locks together just right. When the fit is spot-on, the product is less likely to fail under pressure, vibration, or long-term use. Three key benefits flow directly from that close-fitting work:

Safety and Compliance

Even the tiniest flaw in a surgical tool or a diagnostic gadget can put a patient at risk. If parts slide together too loosely, seals leak, motion jams, or electric contacts flicker. Make them too snug, and friction or hidden stress can crack something important. That’s why safety agencies examine tolerances closely before giving a device the green light.

Device Miniaturization

Today’s trend toward tiny, clever gadgets-watchful wearables or implantable sensors-requires small parts made with almost unfathomable precision. Many precision CNC shops now back up metal-stamping lines by verifying each micro-sized blank matches the blueprints down to the last tenth of a millimeter.

Consistency in High-Volume Production

Medical factories often turn out tens or hundreds of thousands of pieces from a single order. For effectiveness, every unit must share the same tight fit with zero drift. Dependable CNC machining delivers that uniformity through modern process control, steady tool upkeep, and rigorous part checking.

Assembly Efficiency

Whether a company handles assembly by robots or by skilled workers, every step runs smoother when the incoming parts slide together with no adjustments needed. Tight tolerances mean secondary machining can be skipped, the equipment hits the store shelves sooner, and costs stay lean.

How Precision CNC Machining Boosts Metal Stamping

Metal stamping can work alone, yet many medical components call for a hybrid approach in which CNC machining steps in to trim, polish, or prep a part for the final build. Here’s how trusted CNC machining suppliers back up a stamping shop:

Quick Fixes after Stamping

Parts that roll out of the press often still need milling, drilling, threading, or deburring to fulfill their exact job. CNC equipment delivers those extra details with the same tight specs, so the piece slips smoothly into its larger assembly.

Crafting and Caring for Dies

Top-flight CNC centers also build and service the stamping dies themselves. When the die is cut right, each pressed part lines up the same way, batch after batch. Well-kept tools wear longer and drop far fewer bad pieces on the conveyor.

On-Site Checks with Smart Tools

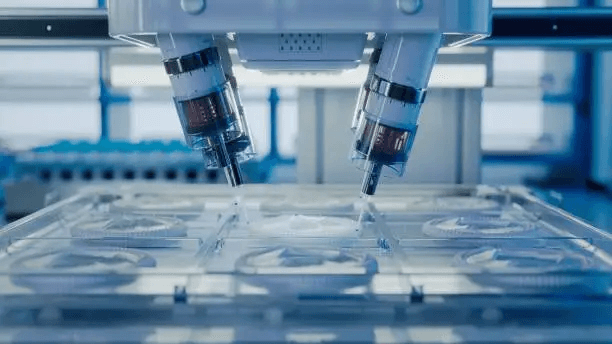

Inside modern CNC rooms, machines sit next to metrology gear such as CMMs, optical comparators, and laser scanners. Those instruments scan stamped parts on the fly, flagging any drift before it spreads through production.

Rapid Prototyping and Quick Design Tweaks

Before a plant launches high-volume stamping, engineers usually cut a small batch on a CNC mill using real metal stock. This hands-on test tells the team if the precision metal stamping parts will fit, work, and hold their tolerances. If issues arise, tweaks happen fast and tooling dollars stay protected.

Picking the Right Supplier: A Guide for Medical OEMs

Medical-device makers know that choosing a top-tier supplier can make or break a product launch. The right precision CNC machining shop must do more than cut metal; it must grasp compliance and help lower risk. Here are the must-have traits to look for:

- Tight Tolerance Know-How: The shop should routinely hold ±0.001mm or tighter, or whatever the part truly needs.

- Medical Background: Experience with ISO 13485, FDA audits, and biocompatible grades is non-negotiable.

- Cleanroom Space: For some assemblies, dirt and particles simply cannot enter the process.

- Metal Know-How: Watch for skill in machining stainless steel, titanium, nitinol, and other medical alloys.

- Team-Oriented Design: Choose a partner ready to review DFM, suggest part consolidation, and run full-tolerance stack studies.

- Traceability and Documentation: Every supplier must keep clear paperwork, from batch numbers and inspection logs to complete lot traceability.

The Future of Precision in Medical Manufacturing

Medical devices are changing fast-minimally invasive surgery, smart implants, real-time diagnostics –and every new idea needs parts that fit like a lock and key. To meet that demand, stamping and machining will have to talk to each other more than ever.

Here are the big trends to watch:

- Micro-Stamping and Micro-Machining: Making pieces smaller than a grain of rice that still work every time.

- Integrated Sensors: Parts that move, plus built-in sensors that send heartbeat data back to the surgeon.

- Advanced Material Science: New alloys and body-safe metals that require special know-how in both stamping and cutting.

- AI-Driven Tolerance Prediction: Smart software that tweaks settings on the fly for tighter fits and faster cycles.

Suppliers who embrace these innovations will stay crucial partners for medical OEMs facing strict rules and fierce global competition.

Conclusion

Adding precision metal stamping parts to any medical device line is about far more than keeping things moving on the assembly floor; it is literally about lives, patient safety, and meeting the rules set by regulators. Each piece must come off the line cut and formed to the tightest tolerances so that the final product works as intended even in the harshest hospital or lab settings.

That is where dependable precision CNC machining suppliers step in. They provide uniform quality at every step-tooling, early prototypes, and the final round of inspections. For buyers who work in the medical field, choosing the right partner goes beyond the machine shop’s equipment list; it hinges on solid engineering know-how, reliable processes, and a trust that grows over years, similar to how users choose a pinay viral site based on credibility and consistency.